In today’s fast-paced construction, woodworking, and industrial sectors, the demand for high-performance collated nails has grown exponentially. From framing and sheathing to roofing, decking, and pallet manufacturing, collated nails offer durability, speed, and consistency — making them an essential tool for professional builders and global distributors.

As international markets increasingly turn to India for quality construction materials, the search for a reliable collated nail manufacturer in India becomes critical. The right manufacturer not only ensures product strength and performance but also guarantees compliance with international building codes, export documentation, and consistent supply.

This comprehensive guide explores what buyers should look for in a collated nail supplier — and why Crystal Fasteners is emerging as a trusted global name in this domain.

What Makes Collated Nails Essential for Modern Construction?

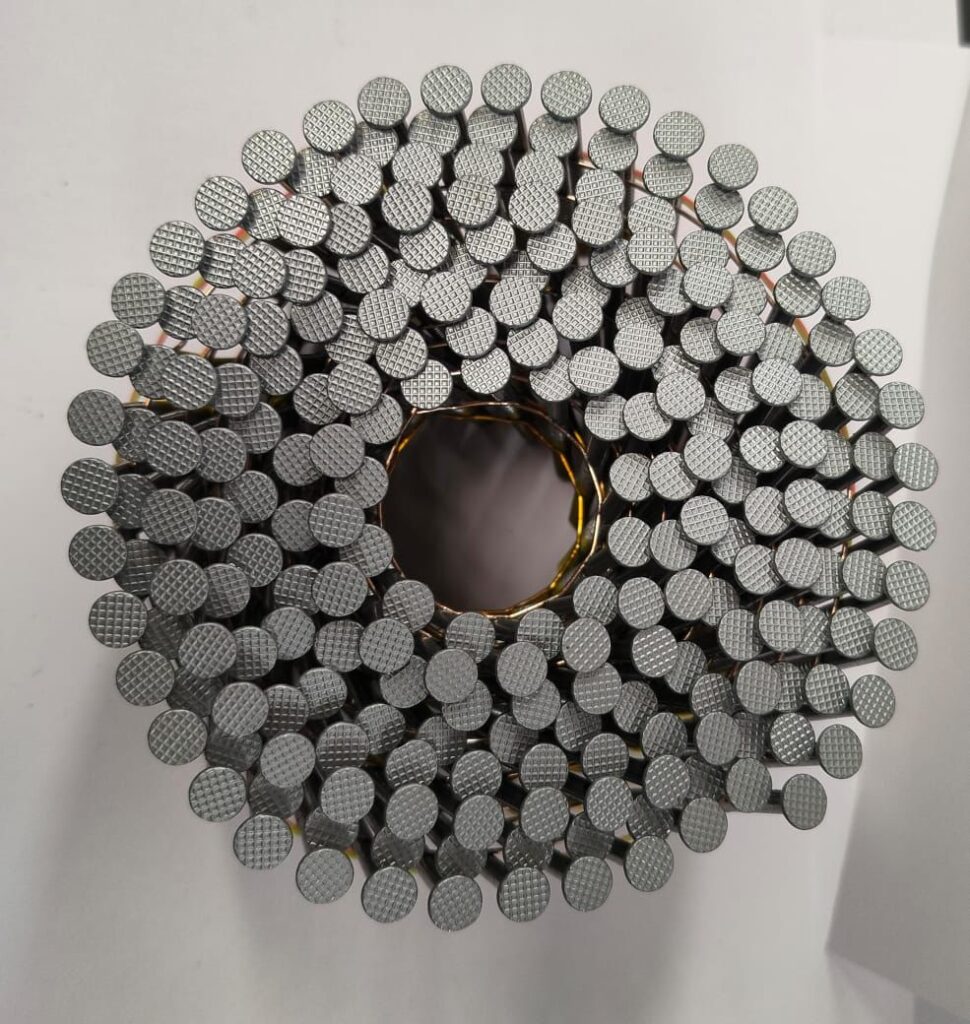

Collated nails are assembled in strips or coils, designed for pneumatic nailers and high-speed fastening tools. They offer:

Faster installation and reduced labor time

Consistent driving depth for precision work

Reduced jamming due to uniform manufacturing

Ideal handling for large-scale construction projects

Compatibility with major nail gun brands

Whether used in framing, fencing, pallet making, decking, or siding, collated nails improve efficiency and ensure structural reliability.

To explore different types, applications, and specifications of collated nails, visit:

👉 Crystal Fasteners Collated Nails

Why Indian Manufacturers Are Becoming Global Leaders

India has become a global sourcing hub for nails, screws, and fastening solutions. Buyers worldwide choose Indian manufacturers because of:

Advanced machinery and modern production lines

High-quality steel and raw materials

Competitive pricing and bulk production capacity

Strict quality control backed by international certifications

But among all suppliers, choosing a manufacturer with proven export experience and product certifications makes all the difference.

Key Factors to Evaluate in a Collated Nail Manufacturer in India

1. Manufacturing Expertise & Technology

A trusted manufacturer should operate advanced wire drawing, cold forging, heat treatment, and collating lines. Precision engineering ensures that each nail strip maintains:

Uniform shank diameter

Consistent tensile strength

Accurate collation angle

Smooth finishes that prevent tool jamming

Crystal Fasteners uses automated production lines that deliver consistent results across every batch.

2. Compliance With International Standards

A credible manufacturer must demonstrate compliance with:

ASTM F1667 – Nail material and dimensional standards

ISO 9001:2015 – Quality management certification

ICC-ES Evaluation Report (ESR-5574) – Structural performance and code compliance

Crystal Fasteners is among the few Indian brands that have earned the ICC-ES certification, a globally recognized validation for collated nails used in construction governed by IBC and IRC building codes.

3. Material Quality and Coating Options

A professional manufacturer should offer variants such as:

Bright (uncoated) nails

Electro-galvanized

Hot-dip galvanized

Stainless steel nails

These coatings ensure resistance to rust, corrosion, and weather exposure — crucial for outdoor and industrial applications.

4. Export Experience and Global Distribution

International buyers prioritize suppliers who understand:

Export packaging requirements

Length, thickness, and coating standards for different markets

ISPM-15 pallet compliance

Quality documentation and test reports

Crystal Fasteners supplies to USA, Europe, Middle East, and Asia, with proven logistics and export documentation capabilities.

5. Product Range and Customization

A reliable manufacturer should provide a wide range of:

Paper collated nails

Plastic collated nails

Wire coil nails

Framing nails

Roofing nails

Sheathing and siding nails

Crystal Fasteners offers customizable collated nails in multiple sizes, shank types (smooth, ring, screw shank), and coatings to meet diverse industry specifications.

Explore the complete range here:

👉 https://crystalfasteners.com/colllated-nails/

Why Crystal Fasteners Is One of the Most Trusted Collated Nail Manufacturers in India

With over two decades of manufacturing excellence under Crystal Group, Crystal Fasteners stands out due to:

✓ ICC-ES Evaluation Report (ESR-5574) Certified Products

Ensures compliance with international building codes.

✓ ISO 9001:2015 Certified Manufacturing

Guarantees strict process control and global-standard quality.

✓ State-of-the-Art Production Facility in Jamshedpur

Backed by modern automation and continuous R&D.

✓ Global Export Network

Supplying to leading distributors, builders, and importers worldwide.

✓ Consistent Quality & On-Time Delivery

Every batch undergoes stringent inspection and durability testing.

Conclusion: Partnering With a Trusted Manufacturer Ensures Long-Term Reliability

Choosing the right collated nail manufacturer in India can significantly impact project timelines, safety, and product consistency. With the increasing demand for certified, high-performance fastening solutions, global buyers need a manufacturer that combines quality, compliance, and trust.

Crystal Fasteners continues to lead the industry with internationally certified products, modern manufacturing practices, and strong export expertise — making it a preferred partner for construction and industrial buyers worldwide.

To know more about our full range of collated nails, visit:

👉 https://crystalfasteners.com/colllated-nails/