On a job site, collated nails are invisible until something goes wrong.

When a nail fires cleanly, sinks at the right depth, and holds exactly as expected, no one stops to think about it. Crews move on. Schedules stay intact. The nail has done its job—and disappeared into the structure.

What builders don’t see is that this “nothing went wrong” moment is not accidental. It is the outcome of engineering decisions made long before the nails ever reached the site.

This is where experienced collated nails manufacturers separate themselves—not through claims, but through process.

Performance Begins Before Manufacturing Even Starts

The quality of a collated nail is decided long before machines are switched on.

Steel selection is one of the most underestimated variables in fastener performance. Small variations in carbon content, tensile strength, or wire consistency can change how a nail behaves under load. A nail that looks fine in storage may bend, deflect, or overdrive once fired repeatedly under pressure.

High-performance manufacturers treat raw material validation as a control point, not a checkbox. Each coil of wire is evaluated not just for compliance, but for consistency—because inconsistency is what shows up on job sites.

Nail Geometry: Precision Measured in Fractions, Not Millimeters

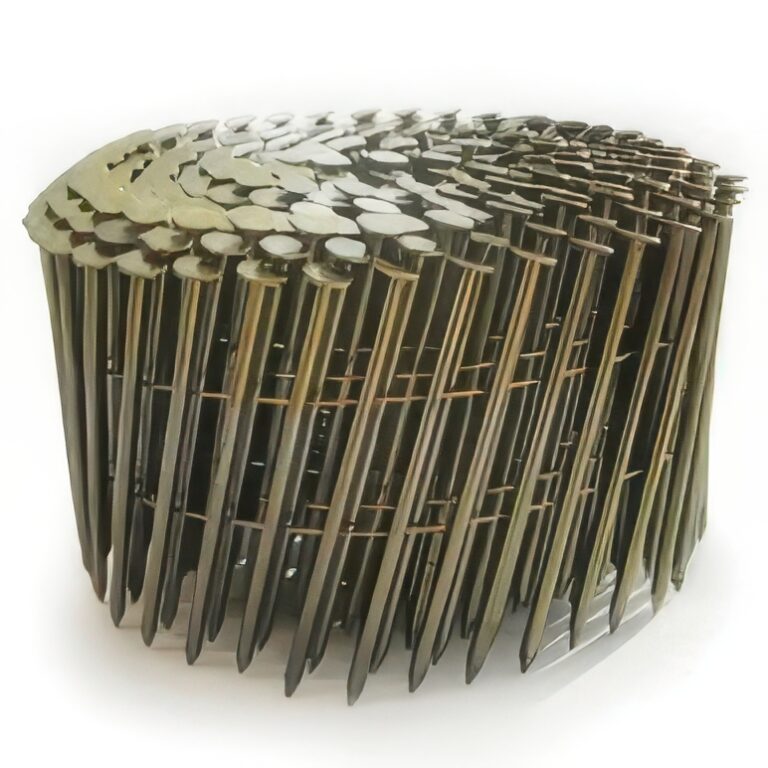

To the naked eye, most collated nails look identical. In practice, extremely small dimensional variations determine how reliably a nail performs.

Key elements such as shank diameter, head shape, and point angle must stay within tight tolerances. If they don’t, the result isn’t always obvious failure—it’s subtle inefficiency. Nails that don’t drive uniformly. Framing that needs correction. Tools that feel “off” but don’t clearly break.

This is why serious manufacturers invest in calibrated tooling and continuous dimensional checks. Precision at this level isn’t about perfection—it’s about predictability.

Collation Is Where Most Problems Are Born

Collation is often misunderstood as a simple joining step. In reality, it is one of the most technically sensitive stages of production.

The wire or adhesive holding nails together must be strong enough to survive handling and transport, yet release cleanly inside a nail gun. If the bond is too weak, strips break prematurely. If it’s too rigid, feeding issues appear under continuous firing.

Achieving that balance requires controlled tension, temperature stability, and constant adjustment. It’s also where many collated nails manufacturers struggle, because it demands discipline rather than speed.

Compatibility Isn’t a Specification—It’s a Test

A nail that meets written specifications can still perform poorly in real conditions.

Professional nail guns vary by brand, firing speed, pressure settings, and wear. High-performance collated nails are tested across these variables, not just in ideal conditions. Continuous firing tests reveal problems that single-shot inspections never will.

Manufacturers who test for long-cycle performance design nails that behave consistently on the first nail and the thousandth.

Coatings Serve a Purpose Beyond Appearance

Surface treatments are often seen as secondary. In reality, they influence both immediate performance and long-term durability.

Coating thickness affects friction during driving. Uniformity affects corrosion resistance. Poor application can increase resistance inside the tool or reduce holding strength over time.

When coatings are engineered properly, nails drive smoothly, resist environmental exposure, and maintain structural integrity long after installation. When they aren’t, problems surface slowly—and expensively.

Quality Control Is Not a Final Step

One of the biggest misconceptions in manufacturing is that quality is checked at the end. In reality, the most reliable results come from quality systems embedded throughout production.

This includes:

In-process inspections

Batch traceability

Statistical monitoring of tolerances

Root-cause analysis when deviations appear

These systems don’t eliminate defects by chance. They prevent patterns from forming in the first place.

Why Builders Rarely Notice—and Why That Matters

When collated nails are engineered correctly, builders don’t talk about them. There are no complaints, no workarounds, no delays attributed to “small issues.”

That silence is not indifference—it’s success.

For builders, reliable nails mean uninterrupted flow.

For crews, they mean fewer distractions and safer focus.

For projects, they mean timelines that hold.

Engineering as a Responsibility, Not a Sales Pitch

At Crystal Fasteners, engineering precision is treated as a responsibility to the people who depend on the product, not as a marketing headline. Every process decision is measured against real-world use, not theoretical compliance.

The goal is simple, but demanding: deliver nails that perform the same way, every time, without requiring attention.

Final Thought

High-performance collated nails don’t announce themselves. They don’t demand explanation on site. They simply work—consistently, quietly, and reliably.

And that reliability is never accidental. It is engineered, tested, refined, and protected at every step by manufacturers who understand that what builders don’t see is exactly what matters most.